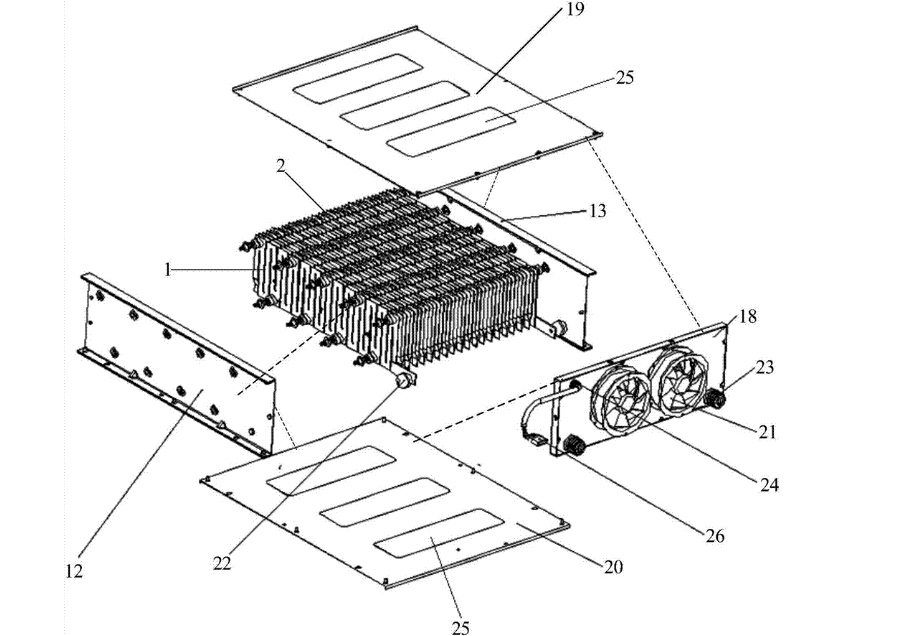

Engineers often use the derating principle when using braking resistors, that is, the nominal power of the resistor will be less than the power consumed during power-on. The braking resistor will also follow this usage rule when it is used. Usually the nominal power of the braking resistor is calculated as: Power value = braking resistor derating factor X average power consumptionduring braking X braking usage %. This type of calculation is often used in frequency converters to accurately calculate the power used by the braking resistor.

In addition, the braking torque calculation needs to have enough braking torque to produce the required braking effect. The braking torque is too small, and the inverter will still over-voltage trip. The greater the braking torque, the stronger the braking capacity and the better the braking performance, but the greater the braking torque requirement, the greater the equipment investment.

Therefore, both the brake unit and the calculation of the braking resistor power must be carefully calculated. If the equipment is working in the limit state, the calculation error may cause damage to the inverter itself, especially when it is frequently braked, and a large amount of energy will be consumed. The capacity of the braking resistor will increase. In this case, it is necessary to accurately calculate the braking resistor power. The engineer needs to repeatedly measure the data when selecting the braking resistor, and obtain reliable data through multiple measurements.