Specification of the pulse load capability is important

The specification of the pulse load capability is becoming increasingly important due to the widespread use of frequency and voltage converters. The pulse load capability is often only exemplarily documented by the specification of one pulse of a certain power or energy and duration. It is rarely specified by listing a table of a few pulse amplitudes and durations. Should the resistor be stressed by a pulse for a duration that is not in the range of those given in the datasheet, and which is not in the range of adiabatic boundary conditions, then it is difficult to calculate the maximum permissible pulse load. However, a combination of theoretical basics and finite element simulations allows for calculating the thermal performance of a resistor over a virtually unlimited pulse duration interval, i.e. from very short pulses to continuous power.

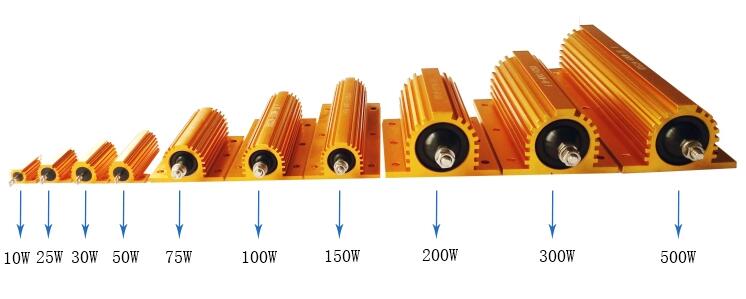

Wire allows for pulse load

Wirewound power resistors, like NUAL series, are typically specified according to their continuous power rating. However, the resistive element, the wire, can pick up a relatively large amount of energy while undergoing only a moderate temperature rise due to its relatively high mass and heat capacity. This is why wirewound power resistors are the perfect choice for pulse load applications.

e-mobility needs pulse load capability

Limiting the charge and discharge current of capacitors is a typical application for wirewound power resistors in the e-mobility sector because of the respective high pulse load. Soldering all electrical components to a PCB may be preferred instead of using “external” resistors, in order to keep the production process as simple as possible. In this case a number of smaller wirewound power resistors are directly soldered to the PCB, replacing a single large wirewound power resistor. For that type of application and manufacturing, Microhm Electronics has put the focus on the PMRY series , which is AEC-Q200 automotive qualified.

Pulse load generates heat

We look at the cooling of a resistor in order to be able to evaluate the effect of an electric pulse load. An effective way to do that is to presume that Newtonian cooling prevails, i.e. that the rate of temperature change is proportional to the temperature difference of the hot resistor and its cooler ambient materials, and that the temperature of the latter is constant. In the case of a cemented wirewound resistor, that ambient material is the cement surrounding the wire. However, the following reasoning can be applied to enameled or sand-filled wirewound resistors, too.

Pulse load at adiabatic boundary conditions

Presuming Newtonian cooling, and hence the proportionality of temporal temperature change and maximal temperature of the wire or resistor, results in an exponential function describing the time-dependent temperature of the wire and resistor.