To achieve accuracy, the Wheatstone bridge is adjusted for manufacturing initial tolerance and ambient and self-heating temperature effects. "Compensation" high precision resistors are then added to correct for bridge unbalance, and to adjust the output sensitivity. Other compensation resistors correct for the errors that result when the transducer is used over a widely changing temperature range. Even though strain gages are very common, acquiring reliable data from them can be a challenge.

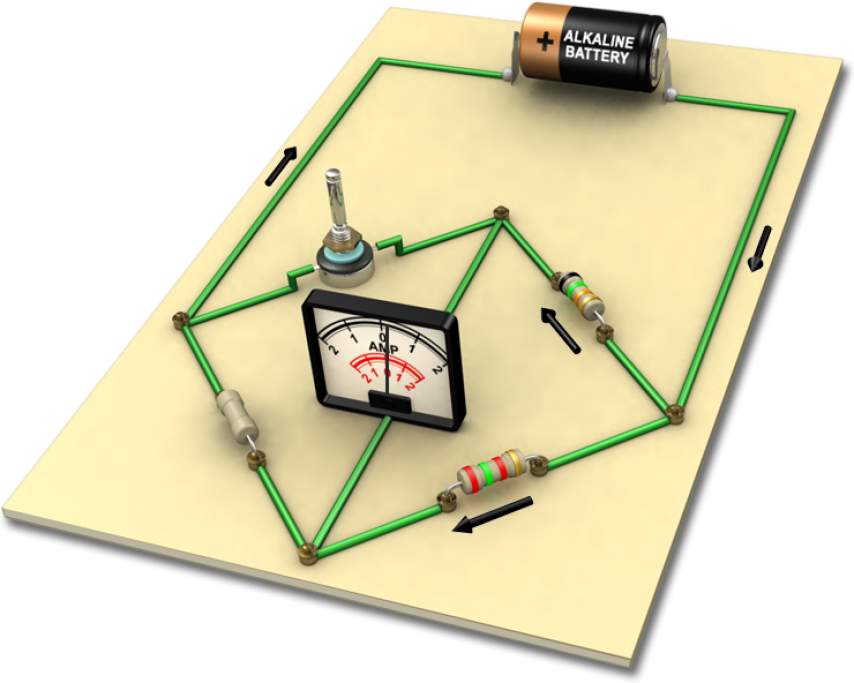

Several factors can affect the measurement performance of a strain gage: the signal conditioning, the construction and location of the Wheatstone bridge (the most common bridge type used to measure resistance), inductance and capacitance, the precision resistors used in the circuit, and the excitation source. Precision resistors have two basic uses in standard strain gage circuits: shunt calibration of strain measuring instruments and bridge completion. In shunt calibration, a fixed high-precision resistor is temporarily shunted across one of the bridge arms to produce a known and controlled resistance change in the bridge circuit. The resulting instrument indication is then compared to the calculated strain corresponding to the resistance change.

In bridge-completion, a precision resistor is used in the adjacent arm of the Wheatstone bridge, and two additional precision resistors are used in the ratio arm. to complete the external half-Wheatstone bridge circuit when a single strain gage is connected in a quarter-Wheatstone bridge arrangement. In each of these applications, the accuracy of the strain measurement is affected, directly or indirectly, by the accuracy and stability of the precision resistors used in the circuit. That’s why only the highest-precision, highest-stability resistors should be used; the choice is basically include Microhm Electronics' high precision metal foil resistor MVR Series, MPR Series and NMS Series.